Author: Luka Dobrovic, PARTICULA Group

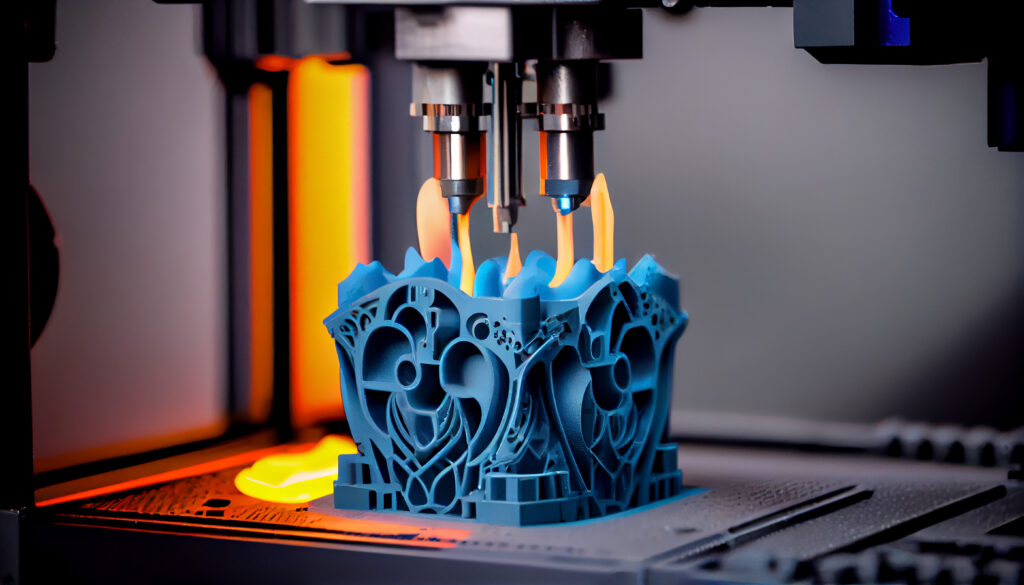

The intersection of 3D printing and sustainability is an extremely optimistic frontier in biotechnology and engineering. One of the key advances of 3D printing is that it reduces wastage of materials to near zero. Whereas traditional manufacturing processes, especially subtractive manufacturing, create vast amounts of waste due to excess material that must be cut away, 3D printing or additive manufacturing builds objects layer by layer with the use of only required material. It saves resources and at the same time minimizes environmental impacts connected with both, the production and disposal of waste. For industries that depend on expensive or rare materials – such as aerospace and healthcare – the savings are even deeper, affecting cost economy and lessening environmental degradation.

Flexibility within 3D printing can be extended to enable localized production, which bears strong implications for reducing carbon footprints. On-site manufacturing that 3D printing enables can reduce the need for transportation of goods over long distances, hence reducing greenhouse gas emissions. In addition, it includes production strategies that involve just-in-time production to minimize large inventories and energy consumption associated with storage and warehousing.

In biotechnology, 3D printing breaks new ground with bio printing – making complex tissue structures that could revolutionize healthcare. In fact, it has huge potential to reduce dependency on animal testing, moving medicine toward more ethical and sustainable practices. Furthermore, the production of sustainable materials, such as biodegradable polymers and bio-based resins, contributes to environmental sustainability through 3D printing. These can be designed to break down safely into the environment, reducing the long-term ecological impact of products.

The flexibility and the versioning capacity that 3D printing offers are therefore as conducive to the practices of a circular economy as they are aligned with the demands of it. This would mean that in design, disassembly can be taken into consideration for easier material recycling at the end of a product’s life. This also helps to reduce the extraction of virgin materials and encourages the reusing of existing ones for a more sustainable industrial ecosystem.

As we advance in the application of 3D printing for sustainability, public education and engagement are crucial. Inspired by all the benefits this technology could bring, such are actions that may spur consumerism and investment in green innovation. What is really needed is simple and easily understandable information on the environmental benefits and societal impacts of 3D printing technologies. This then makes it crystal clear that 3D printing offers exactly an opportunity to couple technological innovation with sustainability targets. Reducing wastes, optimizing supply chains, pushing bio printing, and promoting a circular economy are only a few ways this technology can become incredibly useful in making a better future for all of us. 3D printing capacities must be further explored and extended so that it contributes positively to our environment and social landscapes.