Authors: Author: Bruno Sommer Ferreira, Biotrend

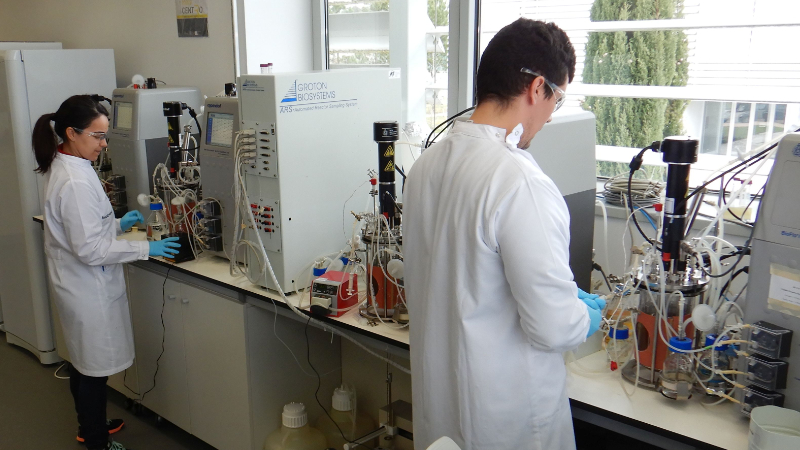

About Biotrend

Biotrend is a research-based company offering advanced services in the area of industrial and marine biotechnology, specialised in the development, optimisation and scale-up of bioprocesses, often based on non-conventional microorganisms and industry-relevant renewable raw-materials. Biotrend operates a state-of-the art development lab and a bioprocessing pilot plant and performs the transition of processes to industrially relevant scales through access to facilities within its network of partners. Our advanced bioprocessing know-how has been serving clients from small biotech startups to global corporations from all across the world.

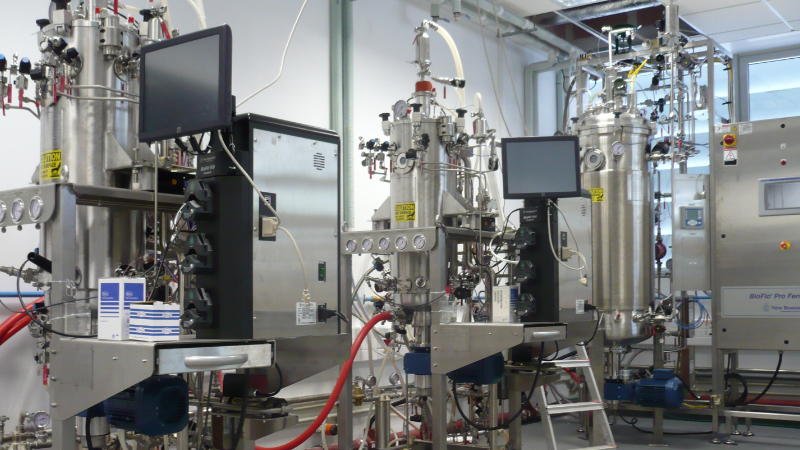

Process optimization and scale-up

When proof of concept of a new process is obtained at lab scale and low TRL (technical readiness level), the next step is the process optimization in order to improve the productivity. This means, increasing the amount of product obtained per unit of equipment capacity and unit of time. Maximised productivity results in lower CapEx (capital expenditures) and OpEx (operating expenses) and hence contributes to the economic feasibility of the processes. Further, a process needs to be validated across successively higher scales, derisking it and making sure that it is robust enough to yield product with the required specifications without deviations from batch to batch at commercial scale. Biotrend’s capabilities have allowed deploying processes, based on renewable resources, to produce microbial biomass and extracts, industrial enzymes, biopesticides, biomaterials, chemicals and nutraceuticals, just to name a few.

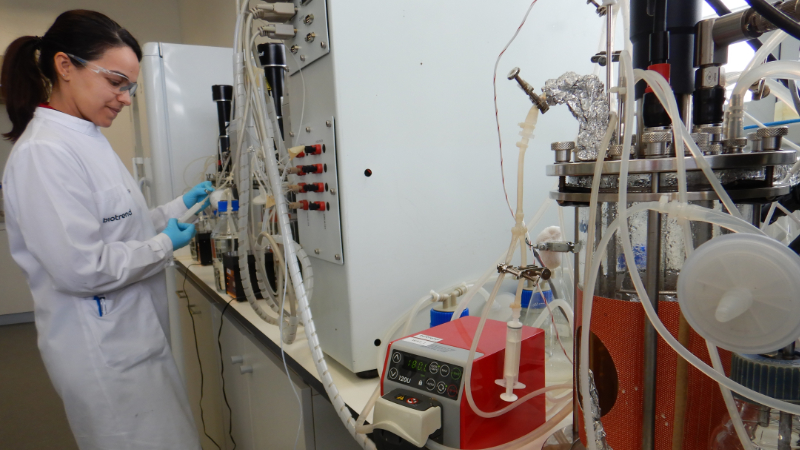

Expertise in production of biopolyesters

Biotrend has more than a decade experience in the research on the production of biopolyesters from renewable raw materials, namely on the production of polyhydroxyalkanoates (PHAs) by naturally producing bacteria, using diverse raw materials. Priority has been given to the conversion of renewable raw materials that do not compete with the food and feed supply chain, focusing on industrial side-streams such as sugars obtained from lignocellulosic hydrolysates from pulp and paper and agro-industrial side-streams, glycerol from the biodiesel industry, and volatile fatty acids from the processing of the organic fraction of municipal solid waste and from anaerobic digestion leachates. For example, within the Bionanopolys project, sugar-rich hydrolysates produced from wood pulp were used by Biotrend as raw materials to produce poly-hydroxyalkanoates, that were extracted and purified to be used in formulations to produce films of biodegradable plastic materials.

Using different carbon sources and tuning the fermentation strategy implemented, it is possible to tailor the polymer properties from rigid to highly flexible and transparent materials. Different monomeric compositions and polymer molecular weight will determine different mechanical properties of the polymer. Additionally, Biotrend has developed intellectual property in the field of the extraction and purification of PHAs using an aqueous process, hence contributing to the increased sustainability of PHA production processes. The hence produced PHAs, with their wide range of properties, can be use in different applications, including, for example, composite materials for the automotive industry, components of multilayer food-packaging materials and mulch films for agriculture.

We thrive on our customer’s challenges

Biotrend is a partner of the Bionanopolys Open Innovation Test Bed (OITB) through which its expertise is put into use. Currently, Biotrend is helping the OITB client Algaesys in the scope of the open call test case “PHAs extraction from microalgae” with the aim to characterise PHA-containing biomass, obtained through the treatment of brewery effluents, and extract PHA from the client biomass using a proprietary aqueous PHA extraction method previously developed, optimised and patented by Biotrend.

Through its expertise, Biotrend serves the motivation of customers to contribute to the circular economy and reduce production costs by redirecting a carbon-rich secondary stream of their process to the production of biodegradable biopolyesters or to incorporate a bio-based and biodegradable biopolymer in their products, a far more environmentally friendly alternative than the fossil fuel-derived plastics.